Flexible Heater Technologies

Custom engineered thermal solutions available in multiple substrates to meet your specific environmental and mechanical requirements.

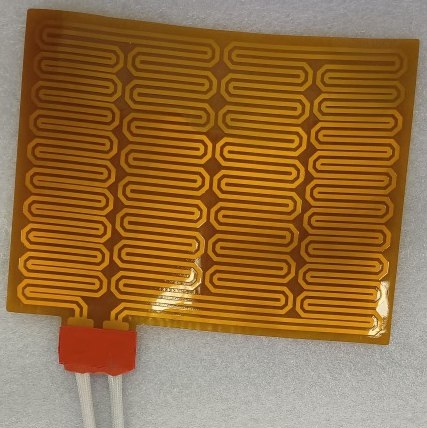

Polyimide (Kapton)

Ultra-thin heaters for space, electronics, and mass-critical systems.

Silicone Rubber

Durable heaters for industrial and high-temperature applications.

Transparent PET

Optically clear heaters for displays, lenses, and glass surfaces.

Performance Comparison

| Technical Parameter | Polyimide Heater | Silicone Heater |

|---|---|---|

| Voltage Range | 0 – 220V | 0 – 220V |

| Thickness | 0.07 – 0.4 mm | 1.0 – 1.5 mm |

| Max Working Temp | 200°C | 280°C |

| Power Density | Up to 1.2 W/cm² | Up to 1.0 W/cm² |

| Service Life | 3 – 5 Years | 3 – 5 Years |

High Performance Material Engineering

Ultra-Thin Architecture

Flexible heaters down to 0.07 mm for mass‑critical and compact systems.

Stable Thermal Performance

Uniform heating with predictable resistance behavior from -40°C to 200°C.

Fully Customizable

Tailored shape, voltage, watt density, and integrated thermistors.

Mission-Grade Reliability

High insulation resistance and zero-defect manufacturing for extreme longevity.

The Engineering Pipeline.

A standardized, 5-stage workflow ensures every heater meets aerospace-grade precision.

Design Capture

Gerber or CAD file ingestion via secure NDA portal.

Thermal Mapping

Ohmic value calculation and watt density validation.

Material Selection

Polyimide grade & adhesive matching for your environment.

Prototyping

Rapid fabrication of 'First Article' for qualification.

Mass Scaling

Full-scale production with zero-defect QC protocols.

Ready for Feasibility Analysis?

Upload your design for a free DFM review within 24 hours.

Start Your Engineering RFQ

Step 1: Mutual NDA

Legal protection for your technical assets.

All shared technical drawings (Gerber/STEP) are strictly confidential under Indian Jurisdiction.

- No disclosure to 3rd parties

- Secure encrypted data handling